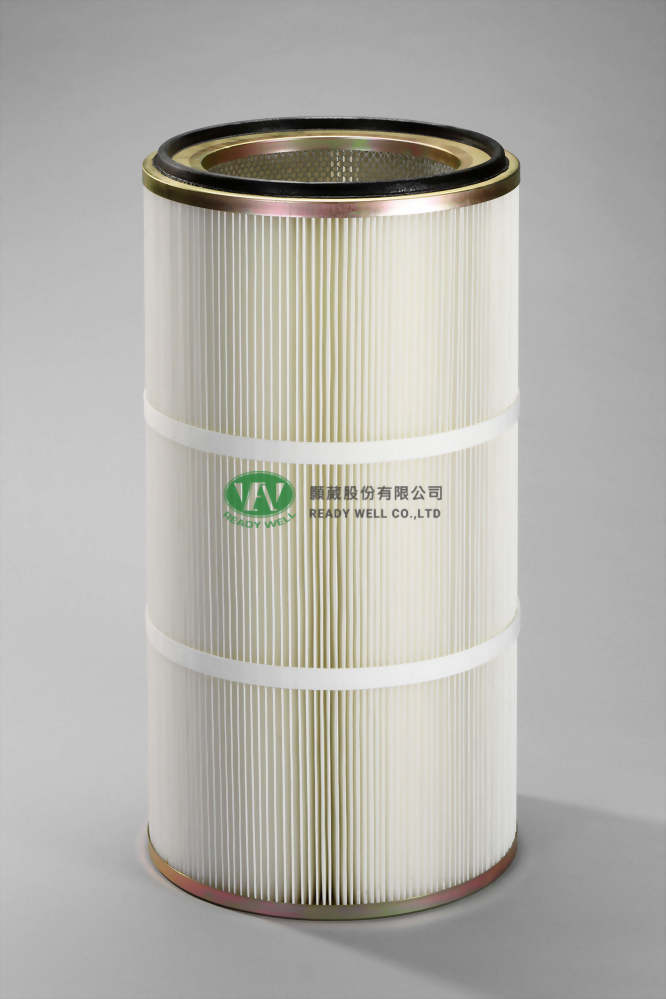

Well-Fib-PTFE magazine type filter

|

Filter material specifications |

||||

|

1.Filter material |

100% Spunbond Polyester Media With P.T.F.E. Coating |

|||

|

2.Dust type |

Cohesive, fibrous and non-fibrous mixed dust, hygroscopic and irregular dust |

|||

|

3.Filter material filtration efficiency |

99.95%@0.2-2micron |

|||

|

4.Filter size |

Shape |

filter area |

Size |

|

|

Ft2 |

M2 |

|||

|

Horizontal filter |

110 |

10 |

12.75”OD × 8.38” ID × 26”L |

|

|

110 |

10 |

13.80”OD × 9.50” ID × 26”L |

||

|

5.Filter material structure |

Horizontal-The upper and lower end covers are fully open, and the material can be galvanized, stainless steel or plastic. -The opening degree of the inner metal support lining is 77%, and the material can be galvanized, stainless steel or plastic. -Synthetic rubber airtight gasket ring, manufactured in one piece |

|||

|

6.Filter material operating

temperature |

120oC |

|||

|

7.Filter certification |

Passes DIN EN 60335-2-69 test method,M-Class standards after IFA testing |

|||

Features of filter material:

- The surface of the filter material is coated with P.T.F.E. (Teflon) on both sides,For hydrophobic filter media。

- Exclusive filter material for cohesive, fibrous and hygroscopic dust。

- The wide pleat design can easily filter dust and use high-pressure air pulses to shake off irregular dust that is cohesive, fibrous, and hygroscopic.

- Can handle hygroscopic dust with moisture content below 5%。

- The filter material can be rinsed once with water。

This P.T.F.E.-coated filter material has a wide range of applications, such as TFT-LCD CVD, SOLAR CVD, PCB, BGA, CCL, metal processing industry, wood industry, chemicals, concrete, food processing, paper, Pharmaceuticals, welding fume, sandblasting, casting, ore processing, various fine particle size dust。